Statistics with Minitab Training Course by SQT

One point beyond control limits. Test Failed at points: 16, 17, 18 The process signals out of control on the lower side at sample 2 and on the upper side at sample 16. Assignable causes occurred after startup (sample 2 – 2) and after sample 9 (16 – 7). (c)... Defining Control Limits - Quality America. Qualityamerica.com The control limits are set in the "tail areas" of the distribution anyway, so that any attempt to fit a …

Control Limits Statistical Process Control GoSkills

Control limits are the voice of the process How to Create a Control Chart Using MiniTab. Other Notes. Also see Rational Sub Grouping. ASQ Six Sigma Black Belt Control Chart Questions . Question: The purpose of using control charts is to (A) determine if the process is performing within specifications (B) evaluate process performance over time (C) determine how to recreate the process (D... The text explains how to set realistic control limits and calculate meaningful process capability indices for non-normal applications. The book also addresses multivariate systems, nested variation sources, and process performance indices for non-normal distributions. The book includes examples from Minitab®, StatGraphics® Centurion, and MathCAD and covers how to use spreadsheets to give

How to Create Control Charts using Minitab 17 YouTube

4/07/2018 · Minitab is a statistics program that allows you to quickly enter your data and then run a variety of analyses on that data. You can quickly prepare charts and calculate regression, and entering data works very similarly to Excel. Minitab... how to use rex 4 Minitab 18.1 Product Key software can be found via numerous vendors in addition to in minitab.com. Finding a permit for 6 or 12 weeks is possible. Minitab may also be retrieved via Penn State’s WebApps service even though there are limits to how it could be utilized from the online atmosphere.

How to Calculate 3 Sigma Control Limits for SPC Latest

Use MINITAB™s random function to generate a pseudo-random data set of 50 normally distributed values with = 200 and ˙ = 30. To run the command from the command how to set up voicemail on iphone 5c ee Control Charts. A control chart displays measurements of process samples over time. The measurements are plotted together with user-defined specification limits and process-defined control limits. The process can then be compared with its specifications—to see if it is in control or out of control. The chart is just a monitoring tool. Control activity might occur if the chart indicates an

How long can it take?

Control limits Wikipedia

- Graded Discrete Nominal Data Assignment Course Hero

- Why do we make the Lower Control Limit (LCL) zero in case

- P CONTROL CHART itl.nist.gov

- Control limits Wikipedia

How To Set Control Limits In Minitab

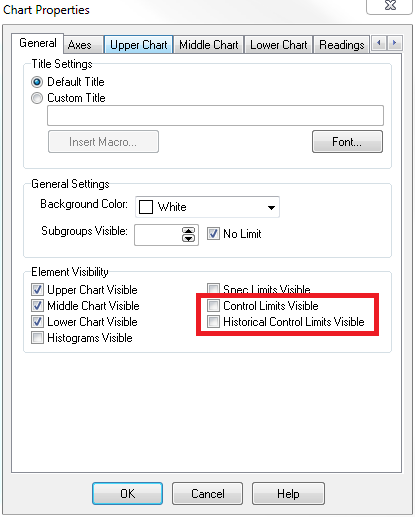

Place bounds on control limits You can specify a lower bound and an upper bound for the control limits. If the calculated control limit is farther from the center line than the value that you specify, Minitab displays the bound instead of the control limit.

- Minitab 18.1 Product Key software can be found via numerous vendors in addition to in minitab.com. Finding a permit for 6 or 12 weeks is possible. Minitab may also be retrieved via Penn State’s WebApps service even though there are limits to how it could be utilized from the online atmosphere.

- The text explains how to set realistic control limits and calculate meaningful process capability indices for non-normal applications. The book also addresses multivariate systems, nested variation sources, and process performance indices for non-normal distributions. The book includes examples from Minitab®, StatGraphics® Centurion, and MathCAD and covers how to use spreadsheets to give

- A commonly used control graph is the XR graph, where the position and spread of the process are monitored with the help of sub groups and control limits. If a point falls outside a control limit on the X graph, the position of the process has changed (see Fig. 16).

- Control Charts This chapter discusses a set of methods for monitoring process characteristics are very difierent from control limits (to follow) which indicate the level of variability expected in a process from its past history and often apply to averages. Charts showing control limits and charts showing speciflcation limits can look very similar so look carefully at the flne print. 4